This snap neck cap is paired with a Preslit PTFE/Silicone septum, made to provide adequate venting and prevent vacuum formation in the sample vial. This creates superior sample-draw reproducibility and eliminates coring from bottom draw-port needles. Laboratories can also benefit from the good resealing ability, making these septa recommended

When it’s time for sample injection, you can trust the PTFE/Silicone Septum from Waters to help you perform that process successfully. Our septa are held to a high standard of cleanliness and dimensional tolerances, as we believe you should only receive the cleanest products from us right out of the box. Tell your lab manager that you need

The Pre-slit Silicone/PTFE of the Cap-mat 96-well Square Plug Pre-slit Silicone/PTFE is able to provide the required adequate venting to prevent vacuum formation, delivering excellent sample-draw reproducibility. It also eliminates coring from bottom draw-port needles while exhibiting good resealing capabilities.

May 28, 2021 · Nevertheless, the loss of tooth substance was significantly greater (p < 0.001) with the silicone technique (−0.29 mm ± 0.02 mm) than with the PTFE technique (−0.15 mm ± 0.02 mm). Conclusions. With the PTFE stamp technique, less healthy tooth structure was removed during the finishing procedure and the stamp was more dimensionally stable.

The preslit PTFE/Silicone septum of the cap is suitable for multiple injections with an operating temperature range from -40 °C to 200 °C. It also eliminates coring from bottom draw-port needles. This septum also provides adequate venting to prevent vacuum formation in the sample vial and delivers excellent sample draw reproducibility.

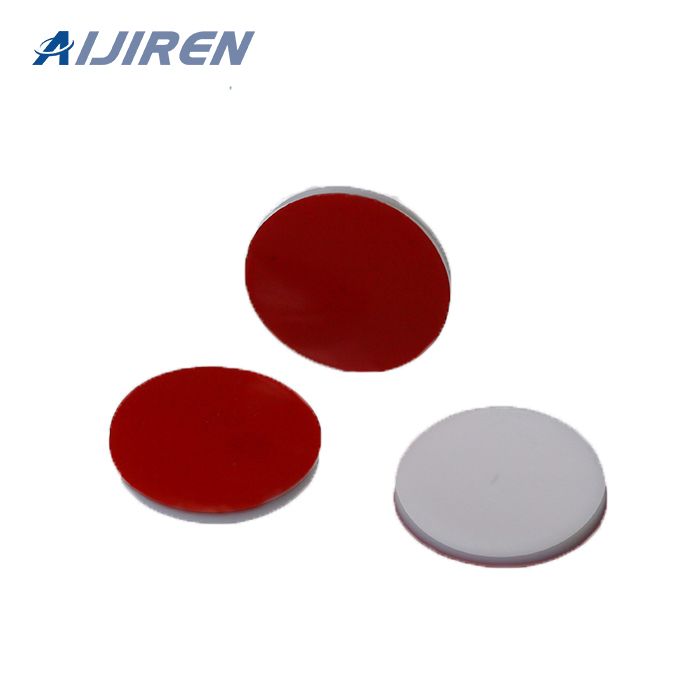

Silicone/PTFE slit Reduces the possibility of coring Alcohols, DMSO, Ether, MethanolUsed to prevent vacuum from forming inside the vial Maximum temperature 200°C Acetonitrile, Acetic Acid, Acetone, PTFE/Silicone/PTFE Superior performance for ultra-traces analysis Above average resealing Most resistant to coring Least evaporation Autoclavable

PTFE coating ensures compatibility. Natural rubber/Ethylene Tetrafluoroethylene (TEF): features excellent resealing properties. Silicone/PTFE: cleanest solution for contaminant free sample handling; autoclavable, too. PTFE/Silicone/PTFE: PTFE laminated to both sides of high-purity silicone to prevent coring.

PTFE coating ensures compatibility. Natural rubber/Ethylene Tetrafluoroethylene (TEF): features excellent resealing properties. Silicone/PTFE: cleanest solution for contaminant free sample handling; autoclavable, too. PTFE/Silicone/PTFE: PTFE laminated to both sides of high-purity silicone to prevent coring.

Prevent material from entering sewers, waterways, or low areas. Soak up with sawdust, sand, oil dry or other absorbent material. Shovel or sweep up. Place in container for disposal. Flush spill area with water. Special Precaution In handling and storage Above 275 °C (527 °F), PTFE PRODUCTS can evolve toxic gaseous products.

Protect contents and prevent carryover. Highly chemically resistant silicone mats with PTFE coating are autoclavable and preconditioned for low bleed. Preslit silicone provides resealability and resists coring or tearing after multiple needle injections. Designed for more effectively sealing 0.45, 1.3, and 2.0 mL plates specifically with square

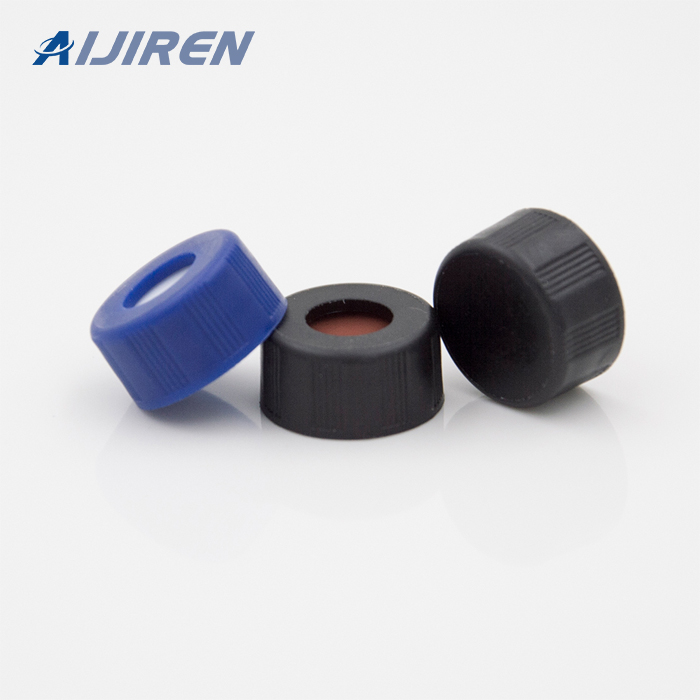

screw caps are available through Waters. This screw cap has a PTFE/silicone septum bonded to the polypropylene cap, using a non-solvent bonding process. This bonding technology is designed to keep the septum/cap together during shipment and assembly onto vials. The bond will aid in preventing dislodging of the septum during

Polytetrafluoroethylene or PTFE is a thread sealant and lubricant. It is used in the piping industry on a large scale to prevent leakage of ducts and pipes. PTFE tape is of many types specified by its area of application. Water PTFE tape is used for residential water pipes, yellow for gas pipelines, and green for oxygen pipes.

(usually silicone) • Tri-layer (also known as a sandwich septum): Still made from two distinct materials – usually silicone surrounded on both sides by PTFE Table 1. Septa chemical compatibility. PTFE/Silicone/PTFE* PTFE/Red rubber Fluoroelas tomer PTFE/Butyl *PTFE/Silicone/PTFE has the same chemical compatibili ty of PTFE only until punctured.

Nov 29, 2018 · Pre-slit PTFE/Silicone Septa. Reduces the possibility of coring with blunt tipped needles or for applications using a thin gauge needle; Used to prevent vacuum from forming inside the vial; Temperature range -40°C to 200°C; PTFE/Silicone/PTFE Septa. Recommended for multiple injections due to above average resealing capabilities

PTFE/silicone – ST101, ST14 • A very pure soft silicone laminated to PTFE. Septum resists coring and is recommended for instruments with fine gauge needles • Also recommended for LC-MS and GC-MS due to high purity PTFE /silicone – ST143, ST144 A very soft silicone laminated to PTFE. Use with flexible needle PTFE /silicone/PTFE – TST1